In the global fashion industry, up to 20% of fabric used in production ends up as cutting scraps—material that’s typically burned or sent to landfills.

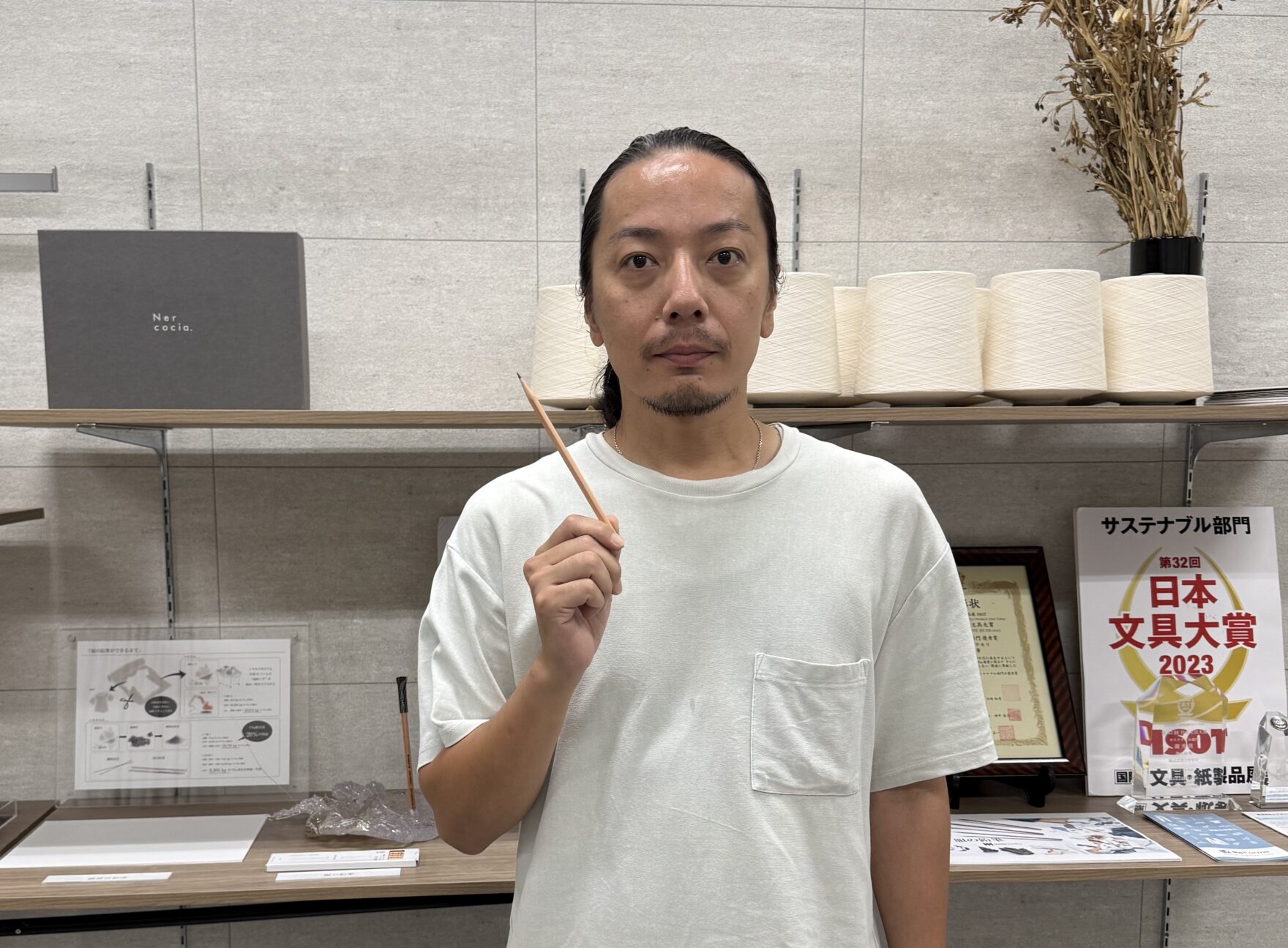

In the small city of Oyabe in Toyama Prefecture, a long-standing Japanese sewing factory is rewriting this narrative. Miyamori Co., Ltd.(https://www.miyamori-co.com/), established nearly six decades ago, has transformed its annual 20 tons of textile waste into something entirely unexpected: pencils.

This simple yet striking idea bridges fashion and everyday life. It’s also part of a broader circular fashion model called “ReForme”, which aims to design clothing with its full life cycle in mind — from production to repair, reuse, and eventual return to the earth.

A Second Life for Textile Waste

What was once treated as waste has been reimagined as a material with new purpose. Miyamori’s process for creating “Clothing Pencils” is both simple and ingenious:

- Fabric scraps are cut into small pieces and thoroughly dried.

- The material undergoes high-temperature carbonization using an indirect heating method.

- The resulting carbon is ground into fine powder.

- About 20% of this powder is blended with pencil lead.

- The lead is paired with a wooden shaft to create the final product.

The pencils have a soft 2B lead and a smooth, matte finish — subtly revealing their textile origin. As an everyday object, they make the concept of circular fashion tangible and relatable.

This innovative approach was recognized in 2023, when the product received the Sustainability Award at the Japan Stationery Awards(https://www.lifestyle-expo.jp/summer/ja-jp/about/isot/award.html). The honor signaled a shift: sustainable design can live not just in fashion runways, but in classrooms and pencil cases.

Education Through Everyday Objects

Miyamori’s initiative goes beyond manufacturing. By partnering with local schools, the company uses Clothing Pencils as a hands-on educational tool.

Children get to see and touch a product made from discarded fabric, learning that resources can circulate rather than end up in the trash. The company estimates that diverting fabric scraps from incineration helps reduce approximately 9.3 tons of CO₂ emissions annually, equivalent to the amount absorbed by 664 trees in a year.

This tangible environmental benefit turns a simple pencil into a bridge between industry and education — an accessible entry point into the world of sustainability.

ReForme: Rethinking the Life of Clothes

The pencil is only one element of a much larger vision. Through its ReForme initiative, Miyamori is building a circular ecosystem that reimagines clothing from the moment it’s made.

The model integrates:

- Repair: fixing hems, seams, and linings to extend a garment’s life.

- Remake: redesigning old clothes into new styles.

- Carbonization: giving fabric a final role as a recyclable material.

This approach challenges the conventional linear model of fashion — produce, consume, discard — and replaces it with a system designed for continuity.

From a Small Factory to the Global Stage

Miyamori Co., Ltd. is set to present its circular fashion model at Expo 2025 Osaka, as part of a program highlighting innovation and intellectual property. By securing patents for its techniques, the company is creating a foundation that allows its model to scale globally and inspire other manufacturers to rethink how clothing is made and reused.

At the heart of this vision is a simple, elegant loop: garments are created, worn, repaired, remade, and eventually returned to the earth. What once counted as waste becomes a resource again, transforming the linear fashion system into a circular one.

The “Clothing Pencil” embodies this idea. More than an upcycled product, it’s a clear, tangible symbol of how traditional manufacturing can drive a new era of sustainability. By connecting environmental impact, educational value, and thoughtful design, Miyamori shows that circular fashion doesn’t need to remain an abstract concept — it can be held in the palm of your hand.

This small pencil represents something far bigger: a future where waste is no longer an afterthought but the starting point of innovation.

Interview partner: Miyamori Sewing Factory — an apparel OEM manufacturer with an annual production capacity of over one million garments.https://www.miyamori-co.coma

![[Switzerland] From Old Railway Workshops to a Sustainable Hub for Work, Food, and Community](https://circulareconomy.tokyo/cms/wp-content/uploads/2025/09/20250408_114905-1500x1125-1.webp)