- Marubeni and Circularise Partner for a More Transparent Supply Chain

- Why Marubeni Chose Circularise for DPP Implementation in Japan

- Current DPP Implementation and Pilot Projects in Japan

- Feedback from Japanese Companies and Challenges in DPP Adoption

- Regulatory Trends: EU vs. Japan

- Mass Balance Approach and Its Role in the Circular Economy

- Future Outlook

Marubeni and Circularise Partner for a More Transparent Supply Chain

Since 2021, Japan’s Marubeni Corporation has partnered with Circularise B.V., a Netherlands-based software startup, to introduce Digital Product Passport (DPP) solutions to the Japanese market. DPP leverages blockchain technology to enhance traceability, streamline mass balance approaches, and improve supply chain efficiency.

To explore the role of traceability systems in the circular economy and compare developments in Japan and Europe, we spoke with Shintaro Kiryu, Manager of the DX Promotion Section, Chemical Products Division IV at Marubeni, and Kotaro Ueno, Project Operations Lead at Circularise.

Why Marubeni Chose Circularise for DPP Implementation in Japan

Kiryu emphasized that as sustainability and resource circulation become core drivers of economic growth, transparent information exchange is critical. Recognizing the increasing demand for traceability solutions, Marubeni approached Circularise to introduce DPP in Japan.

Circularise’s technology has already gained global attention, particularly among Japanese manufacturers. Notable investors include Asahi Kasei, Sekisui Chemical, and most recently, Teijin. Circularise identified Japan as a key market due to its strong green literacy, leading to this strategic partnership.

Current DPP Implementation and Pilot Projects in Japan

DPP is a software tool designed to digitize traceability across supply chains, primarily focusing on industrial products, but expanding into food and construction sectors. It provides transparency into the supply chain history, enhancing consumer trust and safety.

The adoption process typically involves three phases:

- Prototype Project – Initial testing on specific products

- Pilot Project – A more extensive implementation

- Operational Phase – Full-scale deployment with licensing fees

While Europe has already moved into the operational phase, Japan is still conducting pilot projects.

One recent pilot project utilized DPP to track the material flow of recycled PET bottle caps as part of the Japan Circular Economy Partnership (J-CEP) initiative. This project involved:

- Collecting bottle caps at a Kobe City recycling station

- Sorting by color and resin type at Mitsui Chemicals

- Pelletizing the materials at Nihon Yamamura Glass

- Recycling the materials into new products**—bubble cushioning by Kawakami Sangyo and nail clippers by Kai Corporation**

Consumers can scan a QR code attached to the final product to access traceability data and understand the product’s sustainability impact.

Feedback from Japanese Companies and Challenges in DPP Adoption

A survey of participating companies highlighted key requests, including:

- Information on collection locations and periods

- Proof of environmentally friendly materials for downstream industries

- Comparisons of environmental impact between virgin and recycled plastics

Although DPP can technically include all relevant data, balancing transparency and confidentiality remains a challenge. Circularise addresses this with Smart Questioning technology, which selectively controls access to supply chain data based on user roles.

Regulatory Trends: EU vs. Japan

Europe is leading in regulatory-driven adoption, with DPP mandates for batteries set to take effect on February 18, 2027, under the Ecodesign for Sustainable Products Regulation (ESPR). The Battery Passport project in Germany has already outlined key data requirements, including CO₂ emissions and due diligence reporting.

Japan, in contrast, follows an industry-led approach, where sector-specific organizations create voluntary guidelines. The Ministry of Economy, Trade and Industry (METI) plans to establish a Japanese digital information platform by 2025 under the GX Law (Green Transformation Promotion Law).

Mass Balance Approach and Its Role in the Circular Economy

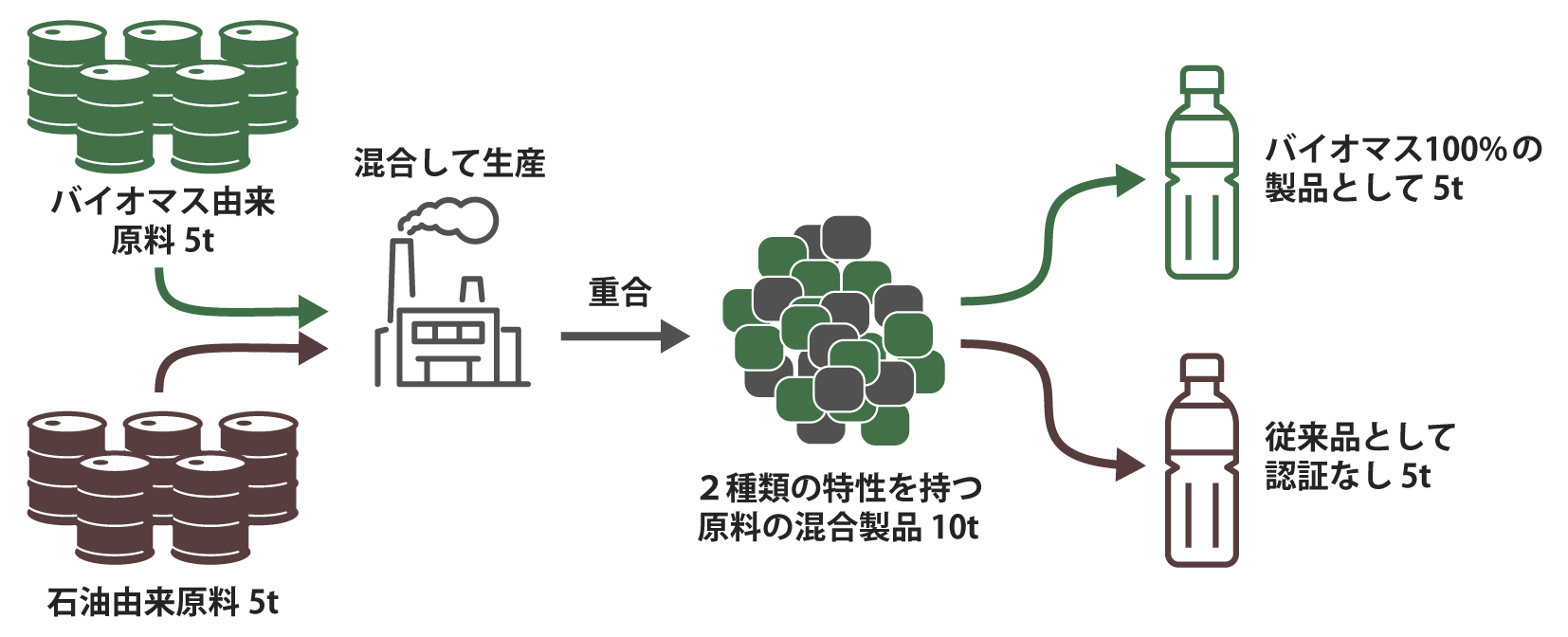

Circularise is also promoting the Mass Balance Approach (MBA)—a method used to track and allocate sustainable material inputs within chemical and energy supply chains.

In industries where raw materials (e.g., recycled, bio-based, and virgin plastics) are processed together, direct tracking is difficult. MBA assigns sustainability credits to outputs based on input ratios, enabling companies to market products as 100% bio-based or recycled, even if they contain mixed inputs.

Circularise’s MassBalancer software automates compliance tracking, reducing reliance on manual Excel-based reporting. It is designed to support third-party certification schemes like ISCC PLUS and REDcert.

This diagram explains the Mass Balance Approach in chemical recycling, showing how biomass-based and fossil-based raw materials are processed together, and sustainability attributes are allocated proportionally through certification.

Input Materials

- Biomass-based Raw Materials (Green barrels)

- Fossil-based Raw Materials (Brown barrels)

Processing Facility

- Raw materials are processed at the factory to create a mixture.

Mass Balance Allocation

- The mixture of biomass-based and fossil-based materials is balanced and assigned proportionally.

Final Products

- Biomass-Based Certified Product (Green bottle)

- Fossil-Based Certified Product (Brown bottle)

Future Outlook

As consumer awareness of product sustainability increases, demand for traceability solutions like DPP is expected to grow. In B2B sectors, automotive and chemical manufacturers with European markets are already investing in traceability to stay ahead of EU regulations.

Kiryu and Ueno believe that, in the near future, more businesses will attach QR codes to products to communicate their sustainability credentials directly to consumers.