Gypsum board is widely used on construction sites, but its disposal has become a major environmental issue. Amid this challenge, one Japanese startup is gaining attention for its innovative horizontal recycling technology.

Today, we introduce GYXUS Inc., a company based in Yokkaichi City, Mie Prefecture.

3.5 Million Tons of Gypsum Board Waste Generated Every Year

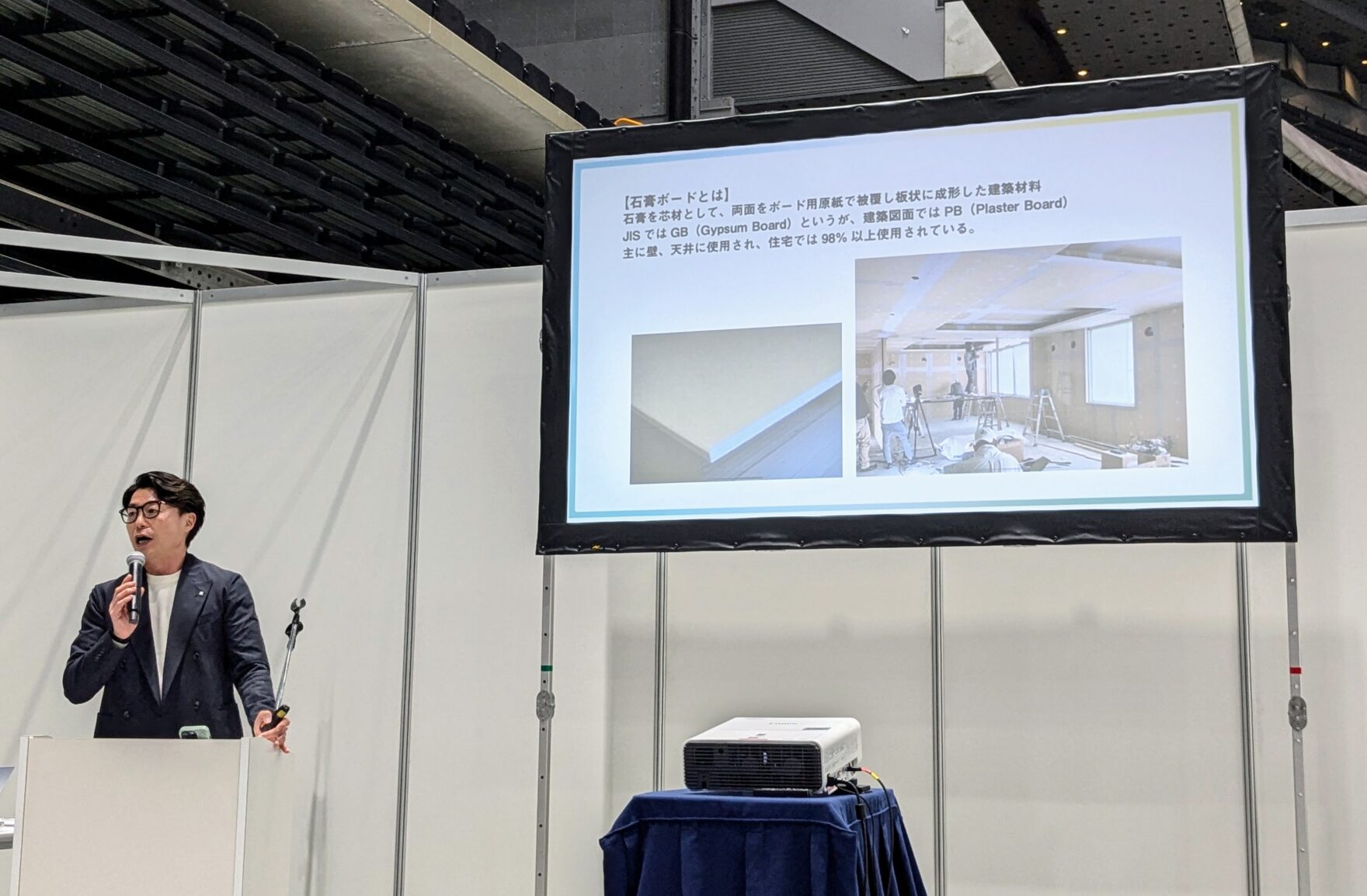

Gypsum board, also known as drywall, is one of the most widely used materials in construction—especially for interior walls and ceilings—due to its fire resistance and affordability. It’s so common that if you peel back the wallpaper in a Japanese home, you’ll likely find gypsum board underneath.

Yet this essential material comes with a major environmental cost. By 2037, Japan is expected to generate over 3.5 million tons of gypsum board waste annually. Most of it currently ends up in landfills, as no practical recycling system is in place. The Japanese Ministry of the Environment recognized the seriousness of this issue in 2023 by designating gypsum board recycling a national strategy in its Fifth Basic Plan for a Circular Society.

If this level of disposal continues, gypsum board alone could overwhelm the country’s landfill capacity within just 40 years. The primary barrier has been the high cost of conventional recycling methods, which often require an expensive process called "large crystallization" to purify the material.

The Founder’s Personal Motivation

GYXUS Inc., based in Yokkaichi City in central Japan, was founded in October 2023 by Tomotaro Hirata. His mission: to revolutionize gypsum board recycling through localized, cost-effective solutions.

Hirata’s roots are deep in the gypsum board industry. His grandfather founded Chiyoda Ute, one of Japan’s major manufacturers. After years of leadership roles in the company, it was acquired by Knauf, a German multinational company and one of the world's largest drywall manufacturers.

While working with Knauf offered new insights, Hirata realized their vision of gypsum recycling diverged from his own.

Driven by a desire to build a system tailored for Japan’s local needs, he left the company in 2023 and launched GYXUS. His new company began developing its proprietary recycling method called GYXUS CORETECH.

How Local Production and Consumption Become Possible

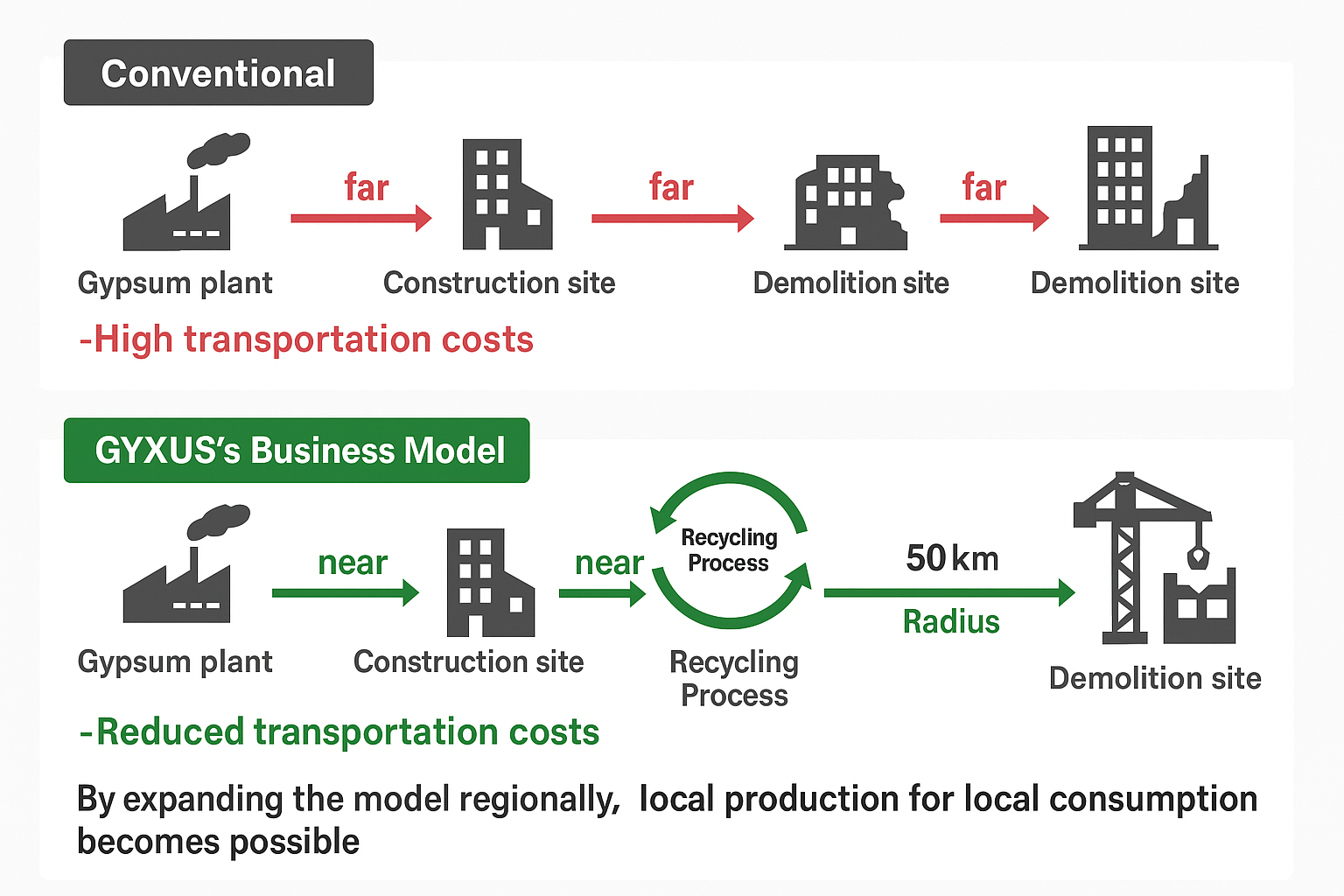

The innovation behind GYXUS CORETECH lies in its ability to recycle gypsum boards without requiring large crystallization. By skipping this costly process, the system reduces both financial and environmental burdens. GYXUS is also pioneering a small-scale plant strategy, which makes it feasible to build compact recycling facilities that serve local areas within a 50-kilometer radius.

This model significantly reduces transportation costs and emissions while maintaining price competitiveness with existing gypsum board products. It also strengthens regional supply chains by linking waste collection (venous logistics) and material distribution (arterial logistics) more efficiently.

“Our approach doesn’t rely on large volumes to bring down costs,” says Hirata. “With the combination of our technology, small plant strategy, and regional logistics, we can realize true local production for local consumption.”

The company promotes this vision at trade shows under the slogan: “Start gypsum board recycling from 500 tons per month.” For example, a single plant in central Hokkaido could cover most of the island’s needs.

Future Expansion in Japan and Beyond

Since winning the Grand Prize at the 2024 Saitama Circular Economy Startup Contest (CSUP), GYXUS has formed partnerships in Hokkaido, Okinawa, Kanagawa, Kyoto, and Saitama Prefecture to develop recycling plants. Plans are underway to expand this model to additional regions.

International expansion is also on the horizon. GYXUS is particularly interested in island regions like Hawaii, where space for landfills is limited and imported materials are expensive. By recycling gypsum boards locally, GYXUS could help reduce waste and lower transport costs at the same time. The company is also exploring opportunities in South Korea and Southeast Asia.

Still, challenges remain. Japan’s current Waste Management Law was designed to regulate waste generators, not to promote circular systems like horizontal recycling. Hirata hopes to see regulatory reforms that support new recycling models.

“Our goal is to build a society where gypsum boards are no longer buried,” says Hirata. “We’re working to make gypsum board recycling a standard practice in Japan—and eventually, around the world.”