Shinei Kasei Co., Ltd.: Over 50 Years of Innovation in Plastic Recycling

Shinei Kasei Co., Ltd.: Over 50 Years of Innovation in Plastic Recycling

Shinei Kasei Co., Ltd. (Headquarters: Adachi-ku, Tokyo) has been a leader in plastic recycling for more than half a century. Established in 1970, the company has remained committed to its philosophy of "reusing finite resources" and has developed advanced methods for producing and distributing recycled plastic materials. By meeting Japan’s strict quality standards and creating an efficient bottle cap collection system, Shinei Kasei has significantly contributed to improving recycling practices. We spoke with Hiroshi Shindo, President and Chief Executive Officer of Shinei Kasei, to discuss the past, present, and future of plastic recycling.

The Evolution of Plastic Recycling

In 1970, plastic was a highly valuable material, costing 20 to 30 times more than it does today. Recycling was primarily driven by economic necessity rather than environmental awareness, as industries sought to maximize the use of costly raw materials. Over time, plastic prices declined, and recycled materials needed to be significantly cheaper than virgin plastics to remain competitive. Today, recycled plastics typically sell for 50 to 70 percent of the cost of virgin plastics.

Recycling has gained renewed importance as global environmental awareness increases. Large corporations are prioritizing sustainability by reducing carbon dioxide (CO2) emissions and maximizing the value of recyclable materials. This trend is particularly strong in Europe, and Japan is following suit, leading to increased demand for recycled plastics. Shinei Kasei currently processes approximately 600 tons of recycled plastic per month, amounting to 7,000 to 8,000 tons annually, using plastic collected from across the Kanto region.

Innovative Technologies and Sustainable Practices

Rather than simply converting plastic waste into pellets, Shinei Kasei specializes in blending different types of plastic to create recycled materials with customized properties. This advanced recycling technology, developed over 30 years ago, has become a core competency of the company.

Initially, Shinei Kasei focused on Post-Industrial Recycling (PIR), utilizing excess plastic from manufacturing processes. However, with growing environmental consciousness, the company expanded its operations to include Post-Consumer Recycling (PCR), processing used plastic products. In 2008, Shinei Kasei also began recycling bottle caps, broadening the scope of recyclable materials.

The company’s bottle cap recycling initiative originated from a movement started by a Japanese high school student in Yokohama, who questioned why plastic bottles were recycled while their caps and labels were incinerated. Shinei Kasei joined the initiative in 2008, launching its bottle cap recycling program. Initially, collection volumes were small, but with the rise of digital communication and increased awareness, bottle cap recycling became widespread. Today, the company processes approximately 5,000 tons of bottle caps annually—equivalent to 2 billion caps—accounting for about 10 percent of its total recycled plastic output.

Developing an effective collection system was key to the success of the bottle cap recycling initiative. Initially, caps were collected from schools and organizations through direct drop-offs and parcel shipping. However, these methods were insufficient to meet growing demand. To scale up, Shinei Kasei partnered with logistics companies to utilize their empty return trips for cap collection, significantly increasing the volume of collected caps.

Today, Shinei Kasei collaborates with multiple logistics firms, establishing a broad collection network across the Kanto region. The primary contributors to this initiative include schools, factories, and corporate offices. While individuals can also participate, the company encourages bulk collections of at least 50 kilograms (approximately 20,000 caps) to optimize efficiency.

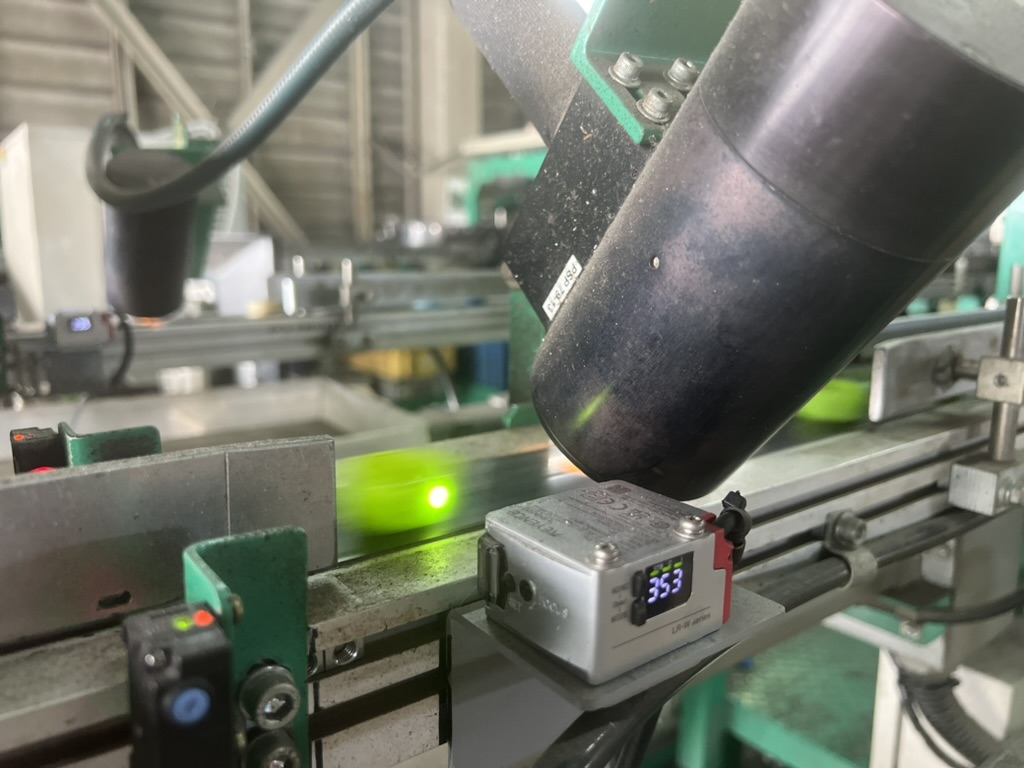

Bottle caps are typically made from two different plastics: polypropylene (PP) and polyethylene (PE). Proper sorting is crucial because mixed plastics lower the quality of recycled materials. Shinei Kasei developed an advanced optical sorting system that accurately differentiates between these materials. The system also categorizes caps by color, as white caps are preferred in material recycling due to their ease of reuse. The sorting process automatically classifies caps into four categories:

- ① White PP,

- ② Other PP

- ③ White PE

- ④ Other PE.

Initially, standard 45-liter garbage bags were used for collection, but they often tore when filled with caps. Shinei Kasei developed durable collection bags designed to hold a specific weight—approximately 10 kilograms when full. This eliminated the need for weighing, allowing for a simple calculation: five bags equate to 50 kilograms, streamlining logistics and improving efficiency.

Recycled Plastics in Everyday Consumer Products

Recycled plastics were traditionally used in industrial applications, such as automotive interior materials. However, they are now increasingly incorporated into consumer products, including supermarket baskets and clear plastic folders.

One of the most notable applications of Shinei Kasei’s recycled materials is in household product packaging. Some shampoo and fabric softener bottles now contain 20 to 30 percent recycled plastic. The company also collaborates with stationery manufacturers to produce clear files made from bottle caps. By making recycled products more accessible to consumers, Shinei Kasei aims to raise awareness about the importance of sustainability.

The Future of Plastic Recycling

The demand for PCR materials is expected to grow as governments and corporations worldwide set ambitious sustainability targets. Japan aims to double its use of recycled plastics by 2030, while the European Union’s End-of-Life Vehicles (ELV) directive mandates that at least 25 percent of plastics in new cars must be sourced from recycled materials. These regulations highlight the increasing global emphasis on sustainability.

Japan faces unique challenges in this industry. The country’s manufacturing sector maintains exceptionally high quality standards, leading to hesitancy in adopting recycled plastics. However, consumer awareness is shifting, and businesses are actively discussing ways to integrate recycled materials into their supply chains.

Shinei Kasei is expanding its recycling efforts to include commonly discarded plastic materials, such as polyethylene coatings from milk cartons. With hundreds of tons of such materials being discarded each month, effective recycling solutions could have a significant environmental impact.

The company also aims to contribute to the advancement of the recycling industry by sharing expertise and fostering collaboration among companies. By improving industry-wide recycling efficiency and quality, Shinei Kasei hopes to accelerate the transition to a circular economy.

Ultimately, the company seeks to change public perception—plastic should not be seen as waste, but as a valuable resource. By choosing recycled products, consumers can play a crucial role in promoting sustainability.

Shinei Kasei Co., Ltd.: https://shineikasei.co.jp/