In Fukuoka, Japan, an innovative company is challenging the norm of discarding used disposable diapers. Total Care System Co., Ltd. (hereafter referred to as Total Care System) has pioneered the recycling of used diapers for the past 20 years, earning prestigious awards such as the Minister of the Environment Award for Promoting a Recycling-Oriented Society. The company holds numerous patents related to diaper recycling and continues to lead the industry.

But how did they manage to achieve what was once thought to be nearly impossible? We visited Total Care System’s headquarters in Hakata, Fukuoka, to learn more from President Takeshi Cho and Executive Director Hironori Sakaguchi.

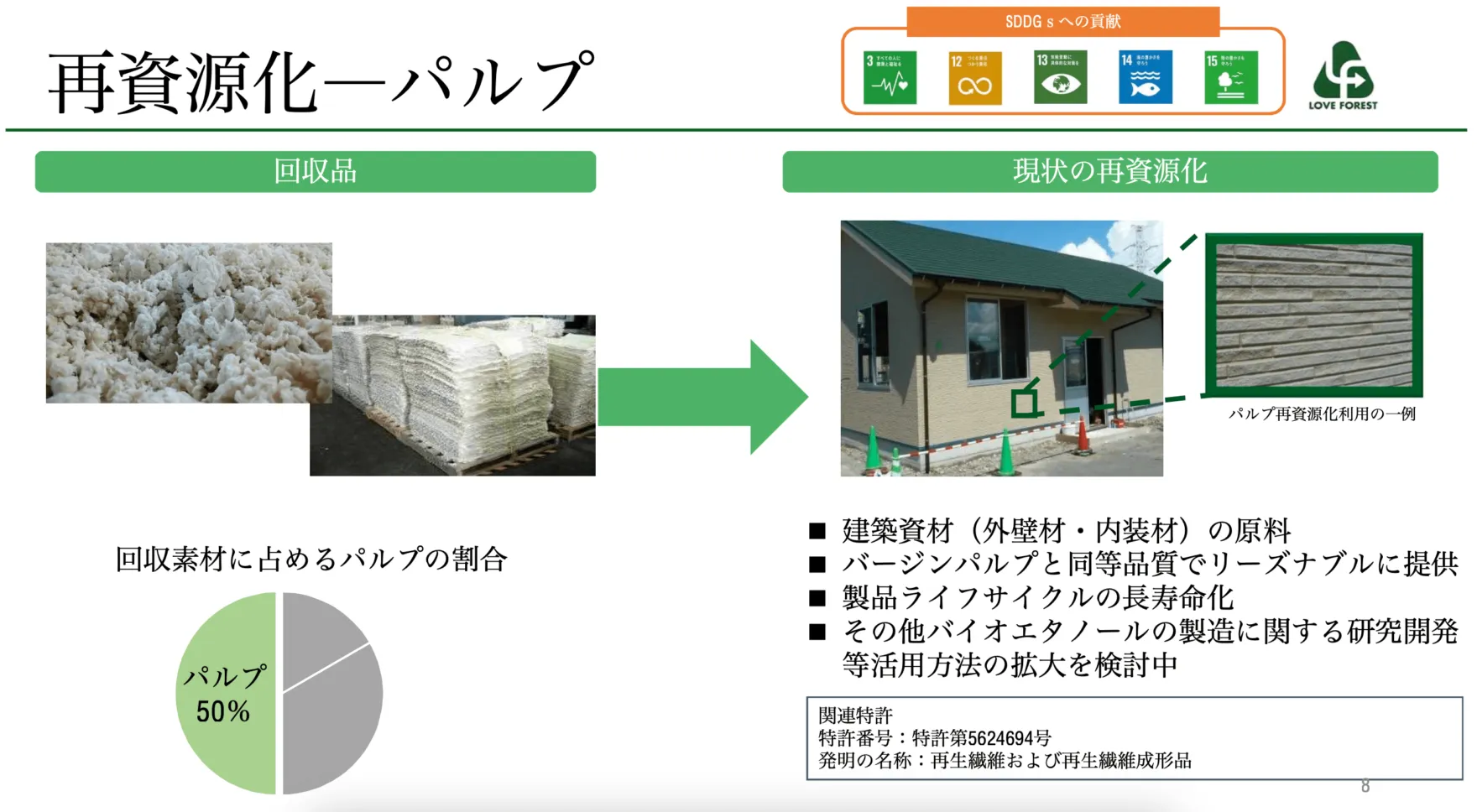

Turning Recycled Diaper Pulp into Building Materials

-Many people may not be aware that disposable diapers can be recycled. How are they repurposed?

These products consist of three main components: pulp fiber, super absorbent polymer (SAP), and plastic. At Total Care System, the recovered pulp fiber is processed into raw material for building products such as exterior and interior wall panels.Each year, approximately 5,000 tons of used diapers are brought to their recycling plant. While only about 30% of this waste is recyclable, around 700 tons of pulp fiber are successfully recovered and repurposed.

-It is surprising that disposable diapers can be turned into walls, but I was also unaware that paper pulp is used in wall construction in the first place.

The idea of using diaper-derived pulp in construction may be surprising, but pulp-based materials are increasingly replacing asbestos, which is banned due to health risks. There are two primary types of pulp fiber: softwood-derived and hardwood-derived. The pulp used in disposable diapers is the same softwood-based fiber commonly found in building materials.

Currently, Japan imports most of its softwood pulp, making it vulnerable to currency fluctuations. However, diaper-derived pulp sourced domestically provides a stable and cost-effective alternative, making it attractive to building material manufacturers. Additionally, the growing global focus on sustainability and the United Nations’ Sustainable Development Goals (SDGs) is driving demand for recycled pulp.

-How are SAP and plastic being recycled?

SAP and plastic are currently utilized as solid fuel for thermal recycling. However, ongoing research aims to achieve material recycling. Future plans include reusing plastic for collection box materials and restoring SAP’s absorbent properties for use in emergency portable toilets.

The idea started with the question, "Why not wash disposable diapers as well?"

-You started working on this recycling business at a relatively early stage. What was the motivation behind it?

Originally, I was involved in laundering hospital linens. Before disposable diapers became widely used, cloth diapers were the standard. As the industry shifted from cloth diapers to disposable ones, used diapers began to be incinerated as waste.

At that time, dioxin pollution was a major environmental concern, and the disposal of used disposable diapers, which contain a large amount of moisture, was also problematic. When I considered alternatives to incineration, it occurred to me—why not wash disposable diapers, just like cloth ones? That idea became the starting point for this business.

-What kind of technology is needed to wash disposable diapers?

I started by conducting a simple test—washing a disposable diaper in a bucket. Based on information from diaper manufacturers stating that SAP (Super Absorbent Polymer) loses its absorbency when mixed with salt, I developed a dehydration method for SAP.

Convinced that this approach had potential, I consulted with my alma mater, Fukuoka University, and in 1997, we devised the "solubilization process", which later became the core technology of our company.

We also conducted research on wastewater treatment after washing used diapers, built a pilot plant for demonstration experiments, and officially launched the business. A student who was part of the research team at that time is now the factory manager of our company.

Establishing a Recycling System with Municipalities

-What challenges did you face in the process of commercializing the business?

Currently, Total Care System collects diapers from approximately 250 facilities, including daycare centers, hospitals, and nursing homes in Fukuoka, Saga, and Kumamoto. However, creating this collection network was not easy. Cooperation from municipalities and institutions was crucial, requiring significant time and effort.

A key challenge was persuading municipalities to change waste disposal habits, as diapers were traditionally classified as burnable garbage. Additionally, they needed to implement a separate collection schedule for diapers, distinct from regular trash.

-Could you tell us about the first municipality that collaborated with you?

The first municipality to collaborate with Total Care System was Okimachi, a town in Fukuoka Prefecture known for its commitment to carbon-neutral initiatives. The town’s mayor personally visited the company’s Omuta factory, leading to the nation’s first municipal partnership for diaper recycling.

One of the factors that ensured the program’s success was the town’s collaboration between its waste management and welfare departments. This cooperation was essential in addressing logistical and social concerns surrounding diaper collection.

-Why is collaboration with welfare-related departments necessary?

To facilitate proper collection, municipalities needed to introduce dedicated diaper disposal bags. However, if these bags were collected like regular household garbage, it could raise privacy concerns for families. To address this, Okimachi implemented a drop-off collection system, placing 60 specialized collection boxes throughout the town. Residents could discreetly dispose of diapers 24/7, eliminating concerns about privacy and odor.

For those unable to bring their diapers to collection points, the local Silver Human Resources Center arranged home pickups. Collection staff operated in male-female pairs, with the male staff handling diaper collection while the female staff engaged in conversations with families. This system not only streamlined waste collection but also served as a community welfare initiative by checking in on elderly residents.

-Are there any challenges in collecting diapers from facilities?

In hospitals and nursing facilities, disposable gloves are frequently used during diaper changes and sometimes discarded along with the diapers. These gloves, made from polyvinyl chloride (PVC), contain chlorine, which disrupts the recycling process. To address this, Total Care System encourages institutions to switch to polyethylene gloves, which do not interfere with recycling. The company also advocates for increased collaboration with product manufacturers to design materials that facilitate recycling.

-How do you plan to expand the business in the future?

Raising awareness that disposable diapers are not "waste" but "resources" remains a crucial challenge. Household diapers, in particular, are easy to separate at the source, making them ideal for recycling programs. In 2020, Japan’s Ministry of the Environment introduced guidelines for used diaper recycling, encouraging municipalities to adopt recycling initiatives.

As the first company in Japan to successfully commercialize diaper recycling, Total Care System has spent 20 years tackling challenges and advancing resource circulation. Moving forward, the company aims to establish diaper recycling as a standard practice, contributing to a circular and decarbonized society.

■Total Care System Co., Ltd:http://www.totalcare-system.co.jp/